Thanks to Covid-19, finding seasonal workers to harvest the globe’s many orchards has become a real problem. However, farmers have found a viable solution in the form of autonomous fruit picking robots.

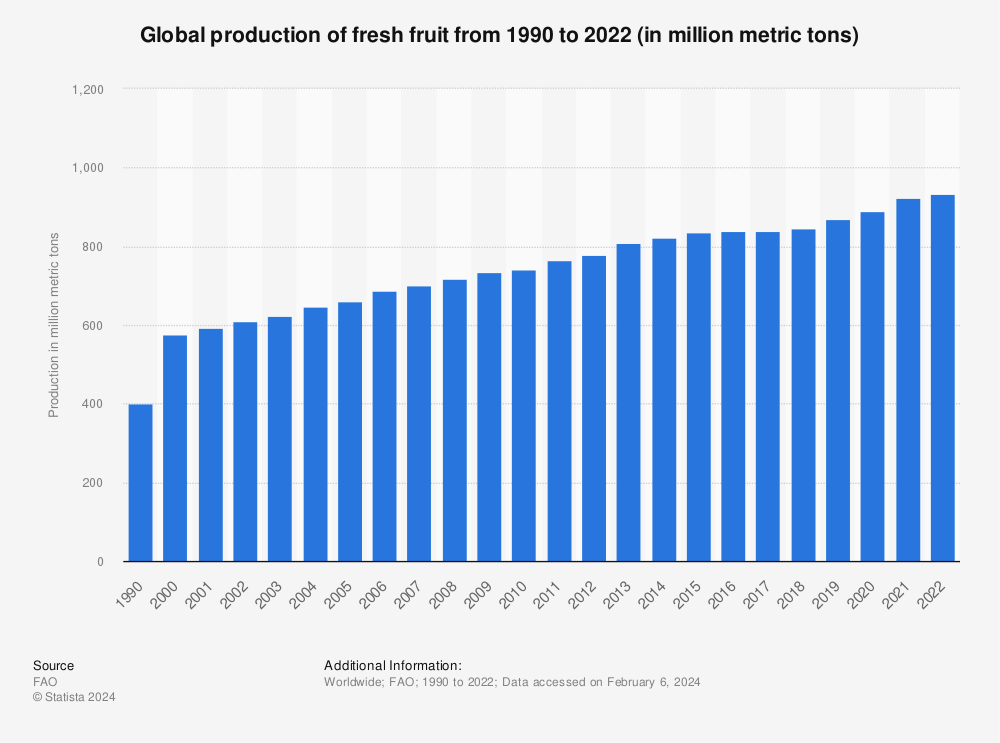

Considering that 800 million tonnes of fruit are produced globally each year, harvesting it seasonally across the world’s many orchards requires an all hands on deck approach.

When it comes to the produce trade, a farm owner’s profitability often relies on their ability to recruit and provide temporary accommodation for trained field workers. When travel restrictions stopped people crossing borders last year, an already sizeable shortage of able fruit pickers became exacerbated tenfold.

European governments appealed to those who had lost jobs in the pandemic to help with harvesting local fruit and veg, and both Spain and Italy offered illegal migrants state regulated work to make up the labour deficit.

2021 is the International Year of Fruits & Vegetables!

A healthy soil and biodiversity are key for a wide array of seasonal fruit and vegetables all year round! What is your favourite fruit or vegetable to eat?

Comment with an emoji 👇#IYFV2021 #FruitsVegYear via @FAO pic.twitter.com/E404KcAlqM

— UNESCO 🏛️ #Education #Sciences #Culture 🇺🇳 (@UNESCO) January 17, 2021

With the long persisting issue now accelerated by the pandemic, the UN has designated 2021 as the International Year of Fruit and Vegetables and is looking for technical innovation to reduce fruit loss and waste.

Up steps Israeli tech company Tevel Aerobotics Technologies, bringing forth its ingenuis solution to bide over farmers: an autonomous fruit picking drone. No, I’m not kidding.

Aptly named the ‘Flying Autonomous Robot’ (or FAR), these nifty drones are integrated with state-of-the-art AI systems and aeronautical engineering.

Able to pinpoint fruit concealed amongst the foliage, its internal algorithms can classify everything from the size and variety of a piece of fruit, to its ripeness – chucking ‘blemished’ fruit aside like seniors in a supermarket.

Your next piece of fruit might have been picked by a robot 🦾

📕 Read more: https://t.co/anUuK85isL pic.twitter.com/w3o6qzOJTa

— World Economic Forum (@wef) February 20, 2021