Scientists at Berkeley Lab have developed a new way to engineer bacteria to produce raw materials that can be made into plastic. They’re completely recyclable.

We probably don’t need to tell you that plastic is bad for the environment.

A major polluter that causes significant headaches around the world, plastics can be found everywhere. From our foods to our seas, it has become a huge pillar of concern in the ongoing climate crisis.

As a result, many alternatives are being developed with the hope of phasing out traditional plastics entirely. One of the latest developments is an innovative method to engineer bacteria to endlessly produce recyclable plastic.

So far, recycling traditional plastics has largely been unsuccessful. Most of it is single-use and even if it does go in a recycling bin, it’s very unlikely to actually be re-used. Nearly all of our waste is still incinerated, thrown into landfill, or sits in our oceans. We’ve literally an entire collection of rubbish known as the Great Pacific Garbage Patch with its own ecosystem, for crying out loud.

Berkeley Lab, a federally funded research and development centre in California, unveiled a new type of plastic called polydiketoenamine (PDK) in 2019 that could be more easily broken down. This meant it was much easier to actually recycle and reuse without compromising on material quality.

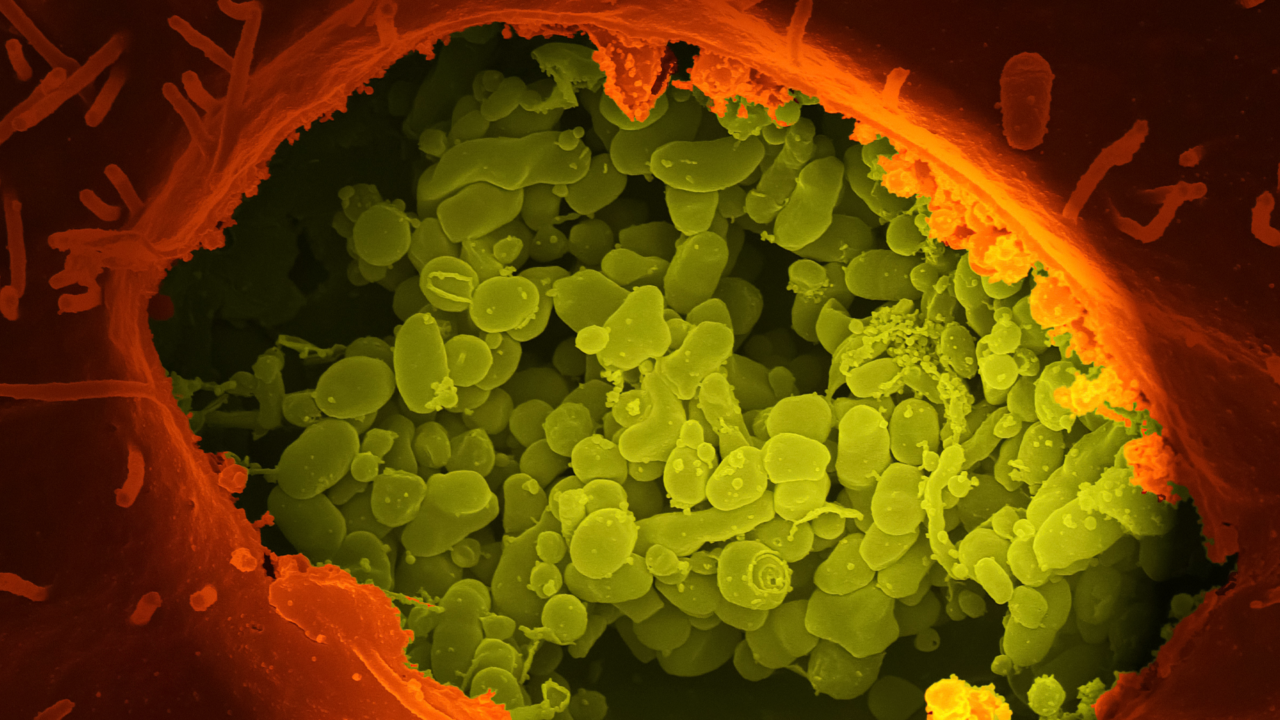

However, while it was a step forward, the PDK was still made with petrochemicals that are used in traditional plastics. Now, Berkeley Lab has successfully switched to a renewable source, engineering E.coli to convert sugars from plants into a molecule called triacetic acid lactone (TAL). This can then be combined with other chemicals, eventually producing PDK.