The world’s first batch of ‘green steel’ produced entirely without fossil fuels is being delivered to Volvo, where it will be used to build electric trucks.

With climate news over the last month being anything but positive, we’re pleased to announce a rare decarbonisation milestone within the industrial industry.

Manufacturing metals currently accounts for around 8% of global gas emissions and has been a constant thorn in the side of collective environmental targets. You can probably count instances of meaningful sustainable change within the industry on one hand.

That being said, Swedish corporations SSAB, LKAB, and Vattenfall may have discovered a way of easing coking coal out of the steel making business for good.

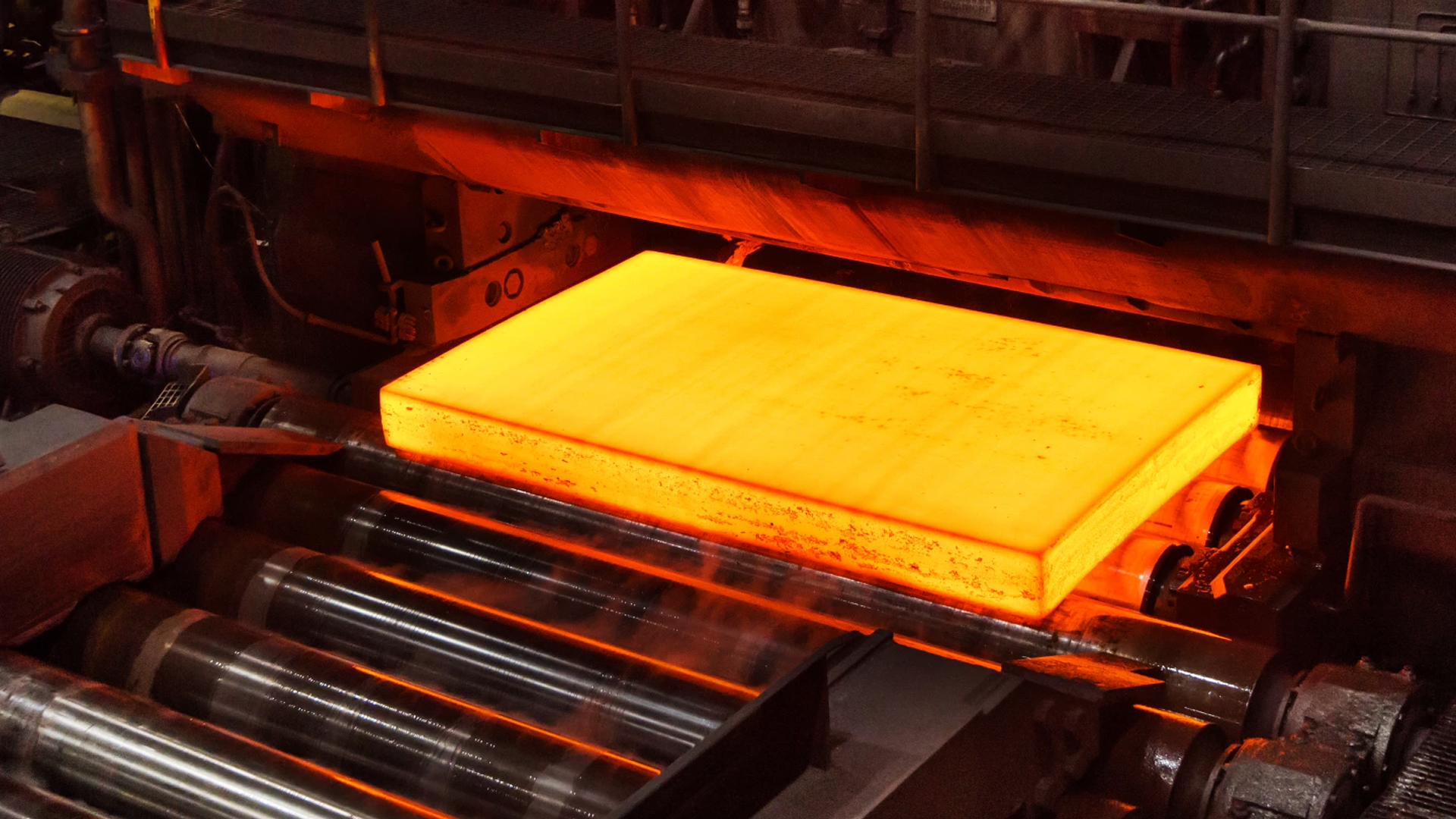

Retiring traditional coal furnaces at a HYBRIT steel factory in Lulea, the Swedish cohort installed hydrogen machines which use fossil free electricity to create mouldable steel ore.

After trials throughout June, reports suggest widescale use of this technology could cut Sweden’s total carbon emissions by approximately 10% and Finland’s by 7%.

Speaking on the recent breakthrough, SSAV CEO Martin Lindqvist stated, ‘the first fossil-free steel in the world is not only a breakthrough for SSAB, it represents proof that it’s possible to make the transition and significantly reduce the global carbon footprint of the steel industry.’

‘We hope that this will inspire others to also want to speed up the green transition.’

Recently able to showcase a successful production line without creating a single carbon emission, SSAB and co have prepared an initial batch of sustainable steel for manufacturers to buy – though prices may be inflated in the product’s embryonic stage.