Already taking up 11% of the Earth’s surface, the agriculture industry is running out of space to keep up with growing food demands. While most innovators are looking to fix the issue with vertical farming solutions, GreenForges is utilising the ground beneath our feet.

When delving into growth projections for vertical farming, it turns out the sky actually does have its limits.

The agriculture industry has constantly battled against a dwindling space issue. For 12,000 years, humanity has levelled entire forests to squeeze farmlands for every square meter, and yet we’re not producing anywhere near enough food to feed the global population.

With 11% of the Earth’s surface occupied by agriculture, science has all but nominated vertical farming – where farms are moved to urban environments, and crops are stacked upright in warehouses – as the obvious solution. Yet, the numbers don’t really add up.

Speaking on a farming research paper, Phillipe Labrie, who founded a sustainable tech start-up called GreenForges, stated that the estimated capacity for vertical farming in cities is ‘a relatively low number.’

‘We’re talking the two to five percent range for the cities of 2050,’ he claims.

For this reason, while most industry experts are looking to the skies for scalable improvements, his company is instead focused on answering a different question: ‘Can we grow underground?’

GreenForges’ underground incubators

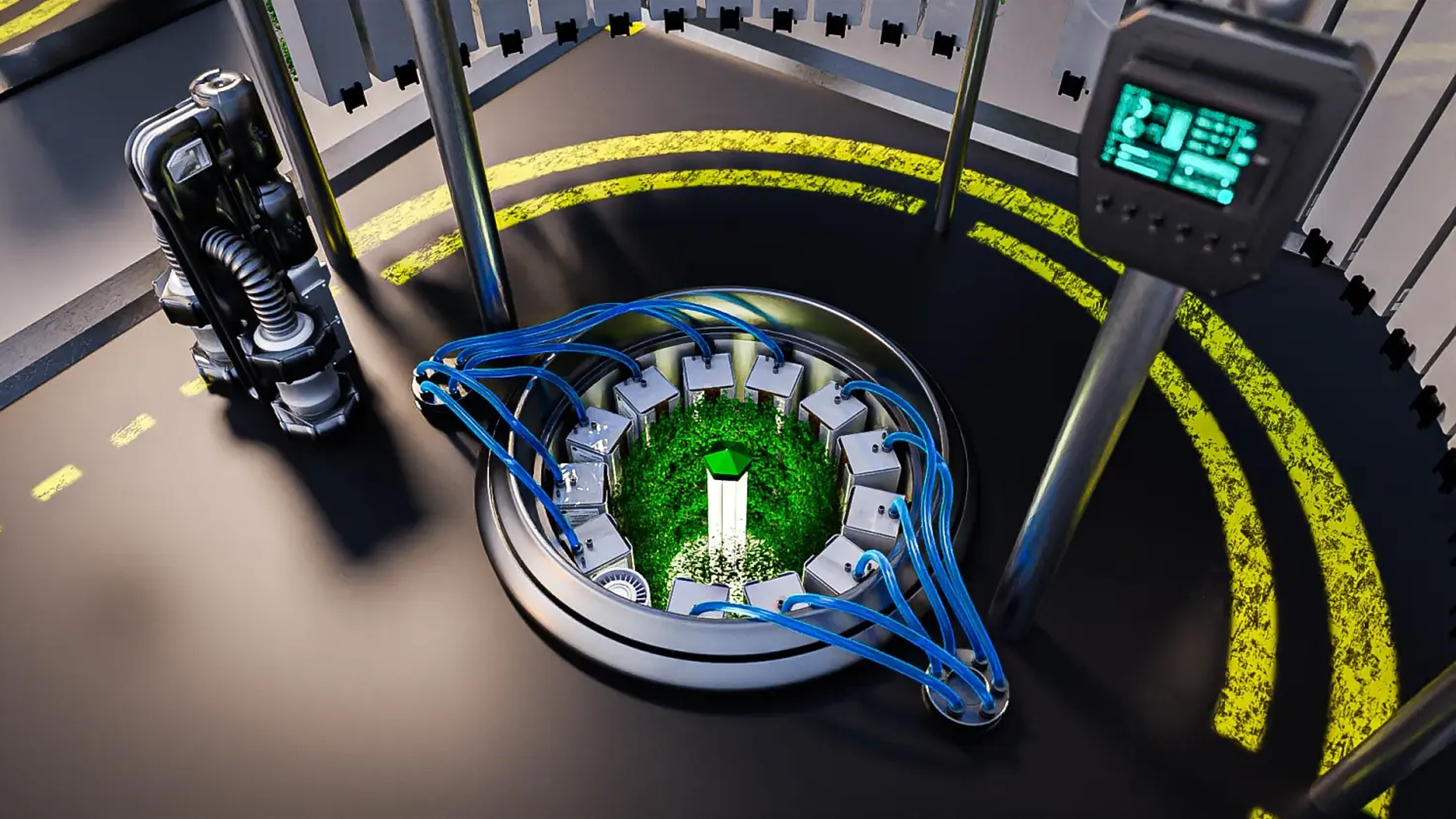

After two years of research and planning into the prospect, GreenForges claims it has developed an ingenious underground incubator which is slated to go into pilot sometime before the end of the year.

Stretching 15 to 30 meters below the surface – where there isn’t much chance of natural photosynthesis – vial shaped housing units will grow crops hydroponically (without soil) through the use of adjustable LED lights, as well as temperature and humidity controls.

Holding traditional indoor crops, like leafy greens, herbs, and berries, GreenForges plans to lower this specially designed equipment into holes drilled in the basements of new buildings. In the official illustrations, the top of each incubator essentially looks like the entrance of a tunnel slide.

Aligned in rows, they’re incredibly effective at maximising space and incubators can be pulled back above ground for daily crop maintenance and picking. It’s an intriguing solution to huge urban warehouses and diminishing natural spaces.

Labrie states that beyond the central aim of saving space and regenerating old farmlands, there could also be a number of secondary benefits to adapting agriculture for the underground too.