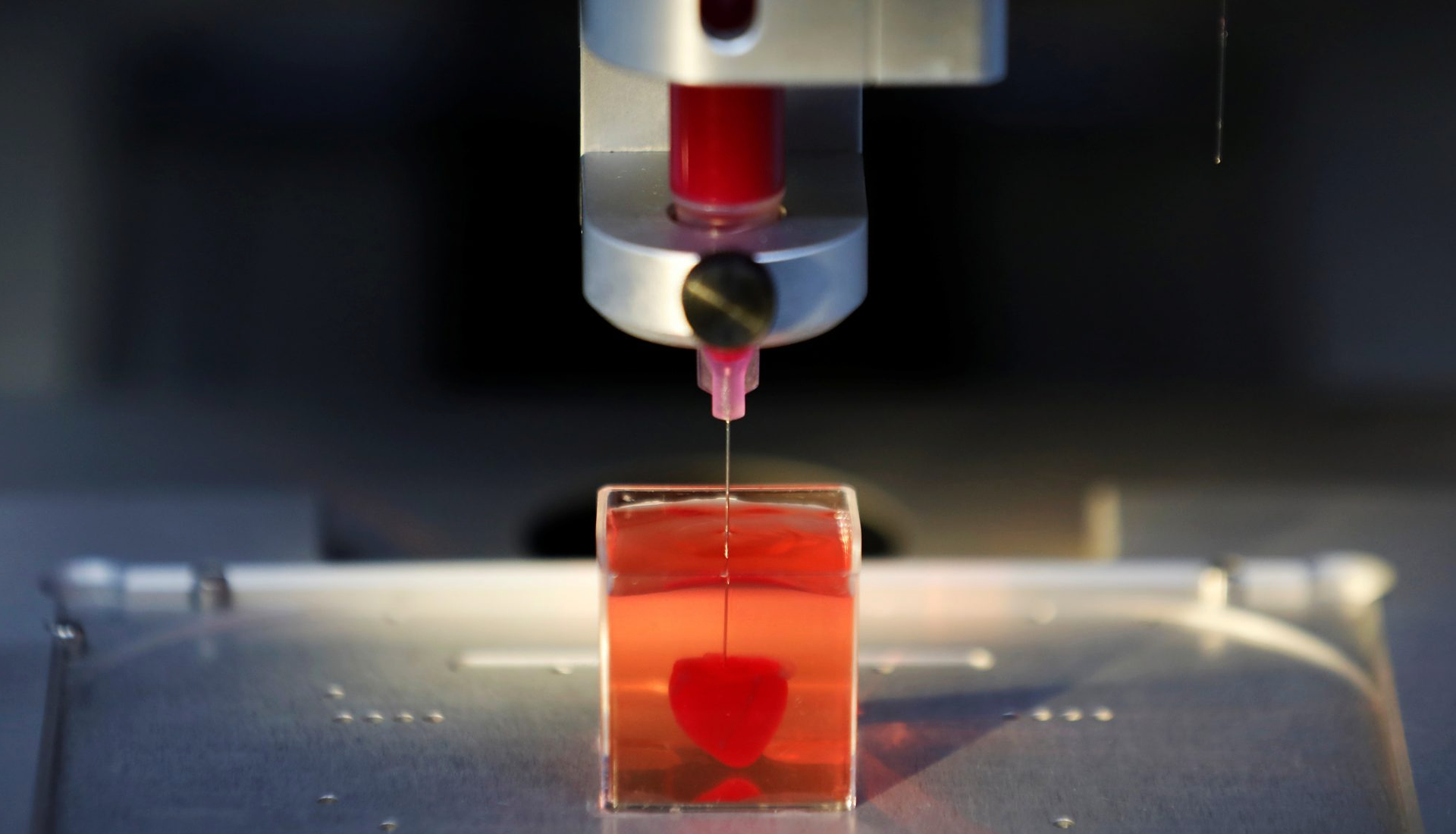

Successful pre-trials have accelerated the possibility for the mass commercialisation of 3D bioprinting and tissue cultivation, and its introduction could save thousands of lives a year.

Last month we included Biotechnology in our listicle for futuristic technologies of the next decade (here), but it appears the introduction of 3D bioprinting may arrive a whole lot earlier than expected.

For those unfamiliar with Biotechnology, it primarily involves Bioprinting: the development of fully functioning artificial organs, and the cultivation of human tissue in laboratory conditions; two processes that once perfected, could usher in a new dawn for regenerative and cardiothoracic surgeries.

Several medical professionals initially expressed concern over the ‘human accommodation’ of artificial organs, asserting that it’s arduous enough getting a body to accept another human heart without inciting a defensive response from the immune system, let alone entirely foreign objects.

But despite the reservations, red tape barring the way to government authorisation is constantly being frayed by the resounding successes of numerous trials in recent weeks.

This month a team of researchers from a diaspora of US Universities collaborated with esteemed bioengineers Jordan Miller and Kelly Stevens – and design firm Nervous System – to perfect a model air sack that mimicked the function of human lungs, delivering oxygen to surrounding blood vessels, creating vascular networks identical to our internal passageways.

A research team pioneered by Zhengchu Tan at the Imperial College London have advanced their techniques for the cryogenic printing of ‘super soft hydrogels’. It sounds awful fancy, but a super soft hydrogel is essentially a material which bears the same ‘soft’ consistency as organs, like the brain or lung.

Tan found that the cryogenic (deep) freezing process enabled tissue to be printed layer-by-layer into intricate three-dimensional shapes, meaning we could feasibly patch small faulty areas of human organs with brand new material. These print ons would act as a ‘scaffold’ onto which healthy cells would be encouraged to grow.