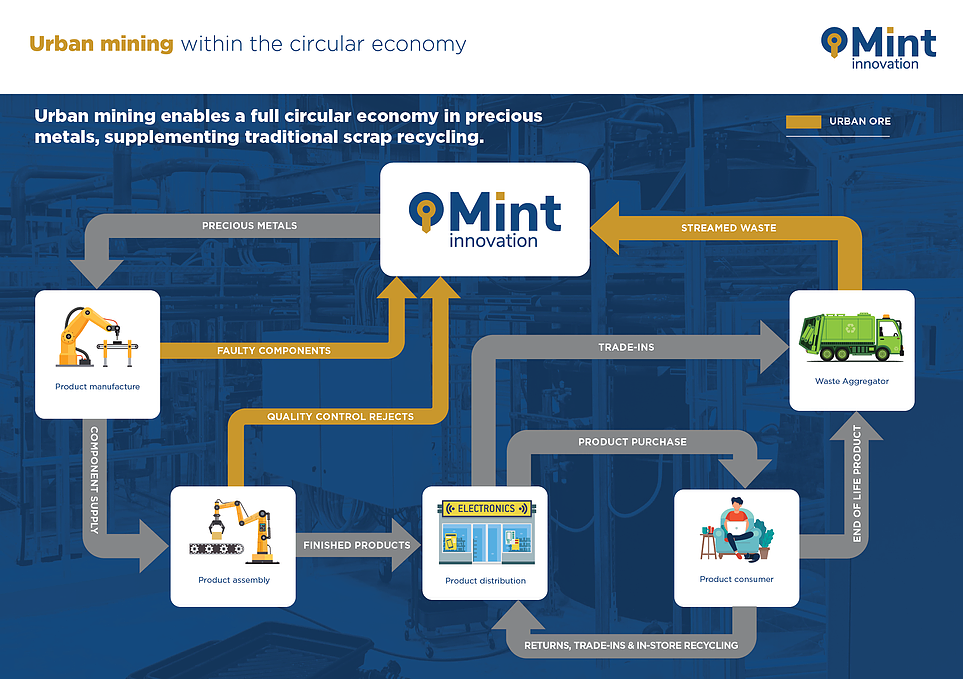

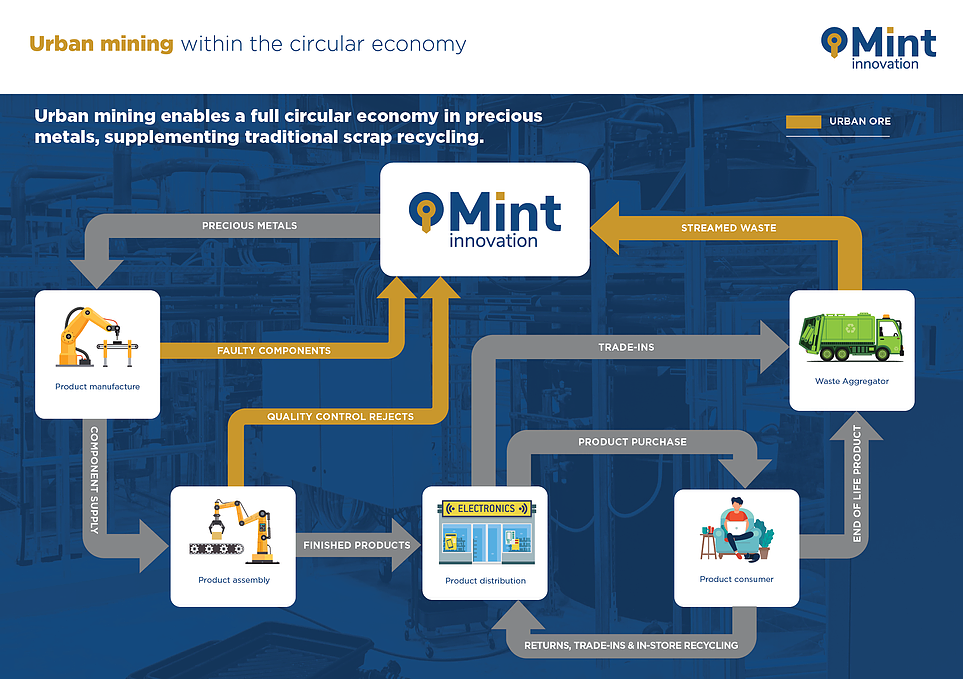

Mint Innovation is a New Zealand cleantech company that uses a clever combination of biology and chemistry to extract precious metals from our ever-growing e-waste.

Ever stopped to think about e-waste?

The likelihood is you have a drawer at home full of old phone chargers, flat batteries, and that one wire with a strange end you’ve forgotten the purpose of but remember is important. I know this because I have a drawer like that too.

Now, imagine the majority of people on the planet also have a drawer like that and you’re beginning to get an idea of how much potential e-waste is knocking about.

53.6 million tonnes of e-waste was produced in 2019 alone, the majority of which was made up of small devices such as irons, kettles, and toasters.

It isn’t all just regular sized houseware though. E-waste can range from large items like washing machines to tiny throwaway objects such as USB memory sticks.

The numbers are made even more alarming when you consider only 17% of e-waste in 2019 was recycled sustainably. In addition, the average 50 million tonnes produced every year is on course to more than double to 110 million by 2050.

What sets e-waste above regular rubbish on the anxiety meter is the toxic substances it contains. When e-waste finds itself in landfill, these harmful elements such as lead and mercury can poison the soil and water.

A lot of e-waste contains circuit boards which house valuable non-renewable resources like gold, silver, aluminium, and cobalt, and extracting and recycling them requires very specific processes and know-how.

Mint Innovation is a company dedicated to this clean up. Its unique process allows precious materials to be recycled and repurposed, thereby reducing the problem of e-waste and offering a climate solution for our discarded goods.

How do they do it?

Step 1: The e-waste is ground up into a sand-like powder. Fair warning though, you probably don’t want to build castles out of this stuff.

Step 2: The powder is submerged in chemicals that dissolve only the precious metals, allowing the undissolved materials to be filtered out. Base metals like copper can then be extracted using techniques like electrolysis (putting an electric current through a liquid to cause a reaction)

Step 3: Microbes are then added to the remaining solution. The gold atoms accumulate on the microbes in a process called biosorption (if you want to impress your science teacher).

Step 4: The gold coated microbes are filtered out as a purple paste which can be refined into recycled gold, ready to be reused. The circular economy in motion.